Factory Intelligence from Shop Floor to Top Floor

A Unified Data Platform Powering Industry 4.0

How we help our customers

Transforming manufacturing operations through intelligent edge computing solutions

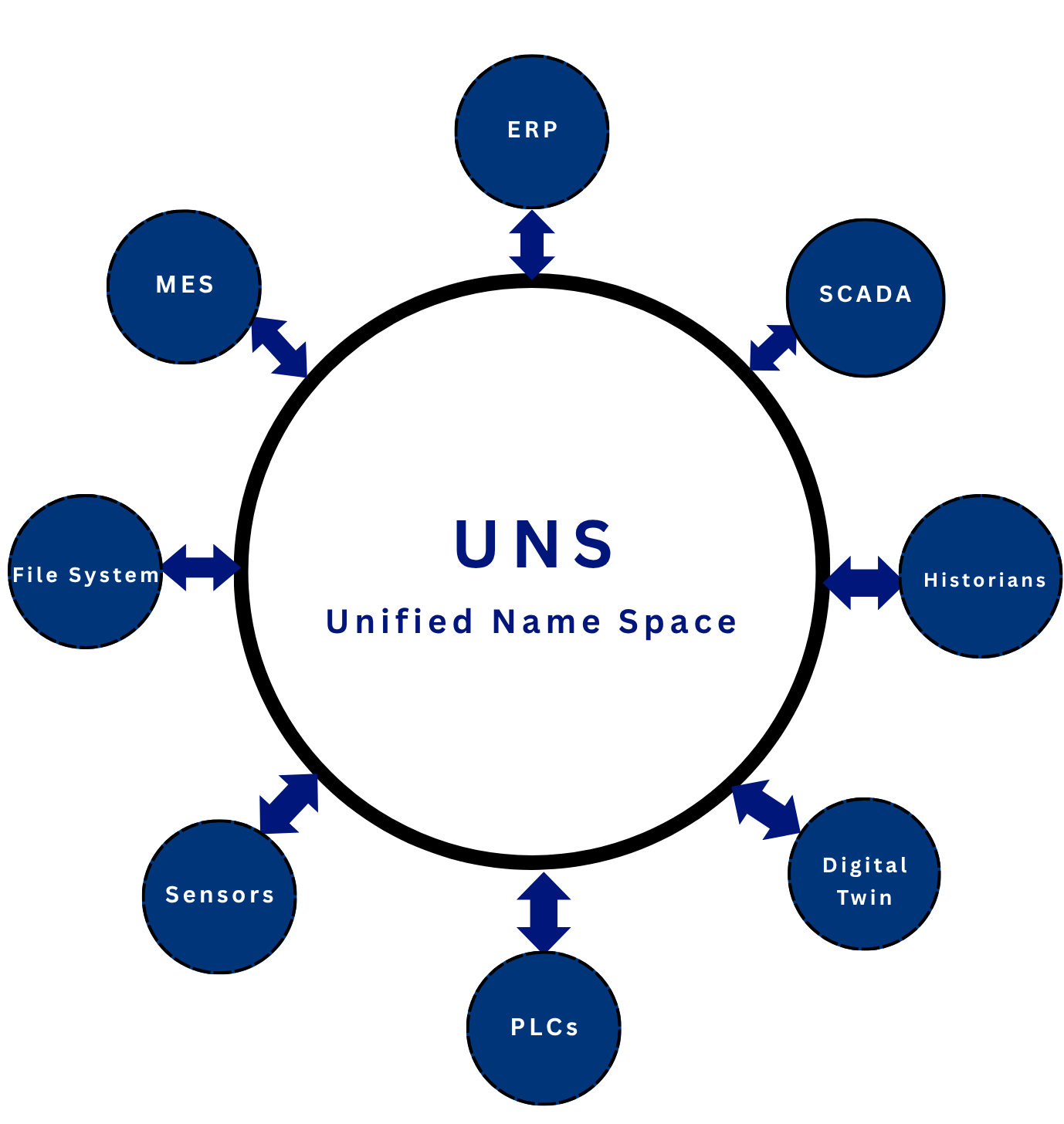

We aggregate data from diverse sources and transform it into meaningful insights, bringing companies closer to Industry 4.0 standards through our edge computing expertise.

Real-Time Processing with Effortless Multi-Source Data Ingestion

Ingest data from sensors, databases, OPC-UA servers, PLCs, files, and Modbus systems in one unified platform

Lift and shift solutions

Transform and contextualize machine data locally with enhanced security, speed, and compliance protection from external threats

Advanced AI analytics

Anomaly detection, alerts, reports, charts, and dashboards with AI/ML integration capabilities

Ready To Use

Easy setup with minimal learning curve, avoiding separate IT teams for infrastructure management

Scalable Solutions

Vertical scaling from 100 to 4000+ data tags support with horizontal scaling for operations.

Tech That Transforms Factories

The future of manufacturing is data-driven, decentralized, and intelligent. Our platform empowers industrial operations to move beyond legacy systems with cutting-edge technologies that bring real-time visibility, contextualized data, and AI-ready infrastructure—all built with edge computing at the core.

Industrial Data Ingestion & Contextualization

- Connect diverse factory data sources—PLCs, OPC-UA, sensors, files, and databases

- Normalize and contextualize data into a unified pipeline

- Unlock clarity, consistency, and deeper operational understanding

Edge-Based Data Transformation & Storage

- Process and store data locally with edge computing for speed and resilience

- Ensure compliance without burdening cloud infrastructure

- Ready To Use architecture enables low-latency analytics

Advanced AI analytics and visualisation

- Deliver actionable insights with powerful dashboards and anomaly alerts

- Generate SPC charts, comprehensive reports, and real-time visualizations

- AI/ML integration optimized for fast decision-making

Comprehensive Platform Features

Everything you need to digitize your factory operations, from data collection to advanced analytics

Real-Time Data Collection

Ingest data from sensors, PLCs, OPC-UA servers, databases, files, and Modbus systems in one unified platform with millisecond precision.

Edge Data Processing

Transform and contextualize machine data locally for enhanced security, speed, and reduced bandwidth usage with our edge computing architecture.

Predictive Maintenance Alerts

AI-powered anomaly detection and predictive analytics to prevent equipment failures before they occur, reducing downtime by up to 50%.

Secure Local Storage

Keep sensitive manufacturing data on-premises with enterprise-grade security, ensuring compliance with industry regulations and data sovereignty.

Multi-Protocol Integration

Seamlessly connect with 15+ industrial protocols and vendor systems without requiring separate IT infrastructure or specialized teams.

Scalable Architecture

Support from 100 to 5000+ data tags with cost-effective dedicated hardware that scales with your manufacturing operations.

Advanced Analytics Dashboard

Interactive dashboards with SPC charts, reports, and real-time visualizations that provide actionable insights for operators and executives.

Ready To Use

24-hour installation with minimal learning curve, avoiding the need for separate IT teams or complex infrastructure management.

Role-Based Access Control

Granular user permissions and access controls ensuring the right people have access to the right data at the right time.

AI/ML Integration Ready

Data layer optimized for artificial intelligence and machine learning integration, enabling advanced predictive analytics and automation.

Offline Capability

Continue operations even during network outages with local data processing and automatic synchronization when connectivity is restored.

Real-Time Monitoring

Monitor machine uptime, performance metrics, and production KPIs with instant alerts and notifications for critical events.

Real-World Manufacturing Use Cases

Discover how our edge computing platform transforms manufacturing operations across diverse industries and applications

Real-Time Production Monitoring

Monitor production lines in real-time with comprehensive KPI tracking, bottleneck identification, and performance optimization across multiple manufacturing units.

Key Benefits:

Industries:

Predictive Maintenance Analytics

Leverage AI-powered analytics to predict equipment failures before they occur, reducing unplanned downtime and maintenance costs significantly.

Key Benefits:

Industries:

Energy Consumption Optimization

Track and optimize energy usage across all factory operations with smart algorithms that identify inefficiencies and suggest cost-saving improvements.

Key Benefits:

Industries:

Quality Control & Compliance

Automated quality monitoring with real-time alerts, statistical process control, and comprehensive compliance reporting for regulatory requirements.

Key Benefits:

Industries:

Multi-Site Factory Management

Centralized monitoring and management of multiple manufacturing facilities with unified dashboards and cross-site performance comparisons.

Key Benefits:

Industries:

Supply Chain Visibility

End-to-end supply chain tracking with real-time inventory monitoring, supplier performance analytics, and demand forecasting capabilities.

Key Benefits:

Industries:

Equipment Performance Analytics

Comprehensive machine performance tracking with OEE calculations, utilization metrics, and performance benchmarking across equipment types.

Key Benefits:

Industries:

Safety & Environmental Monitoring

Continuous monitoring of safety parameters and environmental conditions with instant alerts for hazardous situations and compliance tracking.

Key Benefits:

Industries:

Batch Process Optimization

Optimize batch manufacturing processes with recipe management, process parameter tracking, and yield optimization for consistent quality.

Key Benefits:

Industries:

Edge Computing for Remote Sites

Deploy edge computing solutions for remote manufacturing sites with limited connectivity, ensuring continuous operations and data collection.

Key Benefits:

Industries:

Alarm Management & Response

Intelligent alarm management system with priority-based notifications, escalation procedures, and response time tracking for critical events.

Key Benefits:

Industries:

Shift Performance Analytics

Track and compare performance across different shifts with detailed analytics on productivity, quality, and efficiency metrics.